Medical Capabilities

A Foundation for Device Innovation, Supply Chain Risk Management, and Speed to Market

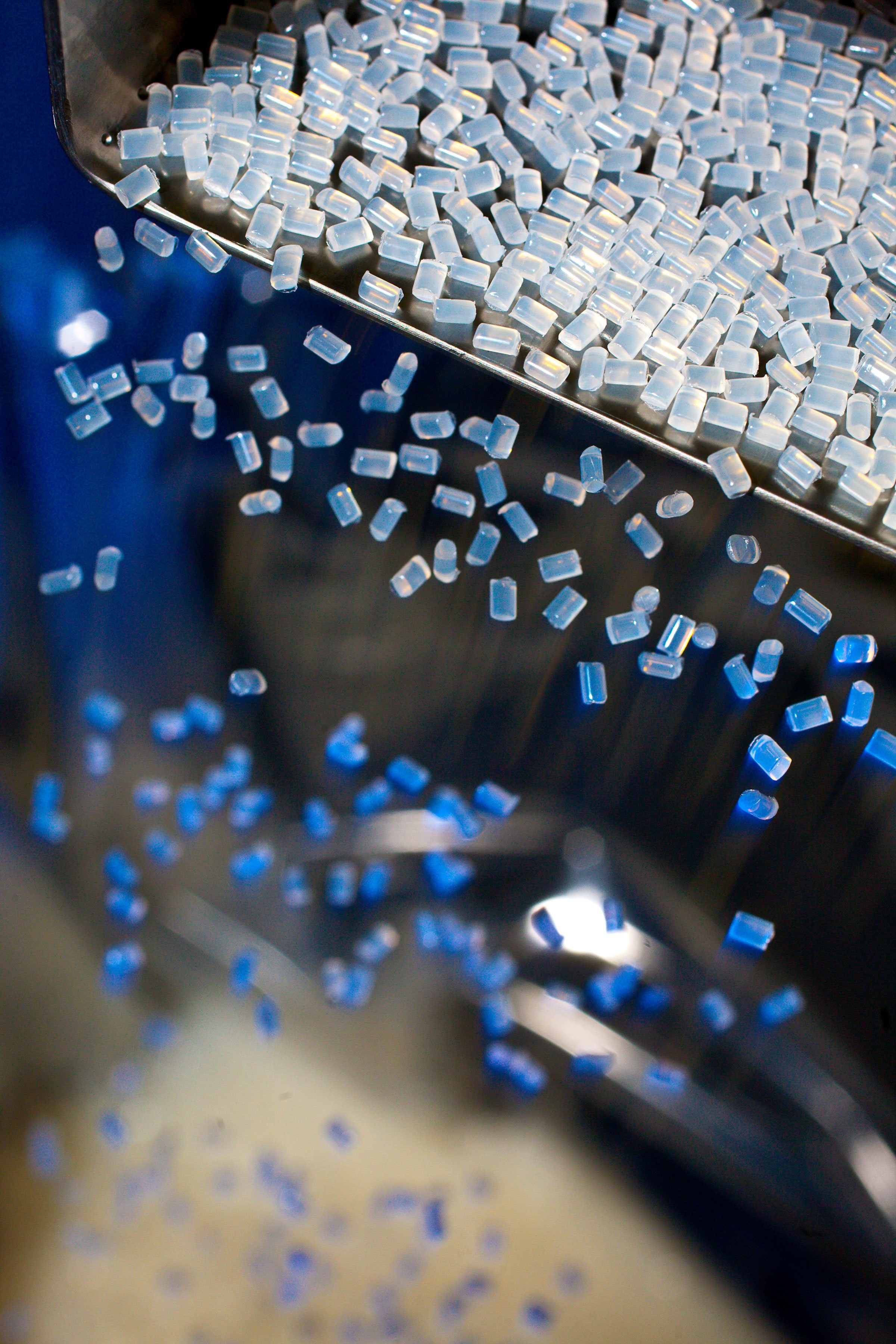

Foster combines specialized facilities, logistics, and quality systems to reduce your supply chain risk and accelerate medical device development. We process all thermoplastic elastomers and thermoplastics across the full temperature range, including high-temperature polymers and fluoropolymers. Our production floor supports underwater pelletization, strand-cut pelletization, and micro-pelletization.

Optimized Logistics: Serving You Coast-to-Coast

With three distinct, strategically located medical facilities across the U.S., Foster offers a significant logistical advantage that ensures material security and rapid delivery. This coast-to-coast footprint — including two facilities in Putnam, CT, and one in North Las Vegas, NV —minimizes supply chain risk, speeds up distribution to major medical manufacturing hubs, and provides localized compounding expertise to quickly scale your medical device production.

View Foster’s Locations

Contingency and Quality in Medical Device Development

Our facilities are the foundation of our business contingency plan. Manufacturing capabilities and protocols are redundant across our Connecticut and Nevada sites, allowing us to seamlessly move production to ensure continuous supply. Furthermore, all our manufacturing facilities are registered to the ISO 13485:2016 and ISO 14001 quality management system, guaranteeing world-class consistency and reliability.

Clean Room: Specialized Facilities and Capabilities

Foster provides cutting-edge facilities to develop and manufacture next-generation implantable materials with unmatched quality, consistency, and reliability. Our flexible infrastructure includes both an enclosed white space for early-stage research and development trials, as well as a Class 7 (10,000) clean room for controlled production. Tailored to specific stages of your product lifecycle, we support your innovation from early research to commercial readiness.

Specialized Capabilities include:

- 27mm twin screw extruder for high-volume output

- 18mm twin screw extruder for R&D-scale development

- Loss-in-weight feeders for precision blending

- Customizable pelletization solutions

- Air- and water-cooling systems

- Sodick precision molding machine for advanced prototyping

- Desiccant dryer and vacuum oven for optimal material drying

- Refrigerated storage for sensitive raw materials

- In-house Inherent Viscosity (IV) testing material characterization

Environmental Isolation Capabilities

Our advanced Environmental Isolation Room is specifically designed for handling hazardous materials and providing superior dust control and fume containment, while also meeting the highest safety and cleanliness standards. This room ensures a controlled environment for precise material processing, secure storage, and employee safety.

Key Features

Enhanced Dust and Fume Control

High-performance air filtration and sealed systems minimize airborne particulates and hazardous emissions, ensuring a safe environment while protecting the integrity of materials.

Temperature-Controlled Processing Environment

Air conditioning and heating systems maintain a stable, temperature-controlled environment to ensure optimal conditions for sensitive materials and prevent temperature fluctuations that could impact material quality and process reliability.

Climate-Controlled Storage Chamber

A dedicated climate-controlled storage chamber is available for raw materials requiring strict temperature regulation to ensure their preservation quality over time.

High-Precision Compounding Line

This system features a 27mm twin-screw feeder and loss-in-weight feeders for precise, consistent material dosing, which is crucial for process uniformity and product quality. The line features customized air and water cooling for strand pelletization, optimizing the cooling process for enhanced product performance. Air cooling is required for bioabsorbable and water-soluble polymers.

Color-Matching Capabilities

Colored polymer components play a crucial role in medical applications by providing both functionality and aesthetics. Colors are used to differentiate a product’s type or size; or to convey warnings (e.g., red for caution). Foster provides precise color-matching services, ensuring color consistency for all your medical applications.

How it Works

Our process simplifies obtaining the exact shade: customers define critical parameters using our Medical Device Design & Color Checklist and submit a target (such as a Pantone number or physical sample). Utilizing both our trained specialists and computerized color matching, we develop precise formulations using either FDA 21 CFR medical device pigments or FDA food contact-grade pigments. We provide custom color solutions for virtually all resin systems: Olefins, Styrenics, Polycarbonate, Polyamide, Polyester, Elastomers (PEBA, SBS, TPU, etc.), Fluoropolymers, High temperature (PEEK, sulfones, LCP, PIE, etc.), Acetal, and Bioabsorbables.

Request a Color MatchColor Methodology

Foster offers two key delivery formats: Pre-colored Compounds (ready-to-use) and Masterbatch/Color Concentrates. Each method has trade-offs based on economics and production volume. Our experienced team can help you select the most appropriate coloring technique for your requirements.

Masterbatch

Polymer masterbatches, or custom-color concentrates, involve pigment concentrates being blended into the natural polymer prior to molding or extruding. This method can provide an economical solution for long, high-volume production runs, as it uses a high proportion of lower-cost unmodified polymers. However, the method requires significant setup time and introduces several risks, such as color inconsistencies or drift throughout the run; as well as moisture pick-up, which can result in an undesirable part appearance, as well as processing or performance issues of the final medical device.

Pre-Colored

Pre-colored compounds are highly reliable and reproducible, a quality critical for regulatory compliance in medical device manufacturing. These polymers are melt-blended and compounded with pigments prior to delivery. This offers significant advantages: they are often chosen for short production runs or projects with smaller material volumes because they save on setup time. They are also ideal for achieving high pigment loadings and are necessary for materials used in thin-wall parts or processed on small production machines, as they provide for substantially greater and more consistent pigment dispersion than masterbatches.

Pigment Selection

Both pre-color compounds and masterbatches can be manufactured using FDA Food Contact Grade Pigments listed under FDA 21 CFR part 173-178 or using FDA Medical Device Pigments listed under FDA 21 CFR Parts 73 and 74. For medical applications, the selection of one pigment classification over the other may affect the FDA approval process.

End-to-End Application Development

We transform your medical device concept into a market-ready reality using our structured, five-phase development process. From initial feasibility testing and custom polymer formulation to rigorous OQ/PQ validation and commercial-scale production, we partner with you to ensure speed, precision, and reliable results.

View Our Development Stages